- Home

- Helicopter External Load

- Helicopter Longlines

Helicopter Longlines

Our line of helicopter longline systems represents a transformative evolution in aviation, enabling versatile external load operations that are essential for utility tasks, firefighting, human external load missions, and cutting-edge UAV applications.

Type of longline:

- Barry Helicopter Longline

- Barry D.E.W. Line® Dielectric Helicopter Longline

- Barry Specialty Longline

Barry helicopter longlines are supported by Airworthiness Analysis to FAA CFRs, CARs and EASA requirements, and are used in over 75 countries worldwide. These products carry a 10-year service and shelf life, and many will include EC/CE Compliant Markings for Europe.

Product selection

Barry Helicopter Longlines

Heavy-Lift Helicopter Longline

Product Code: DLH

Helicopter Longline (Wired)

Product Code: DLL

Helicopter Longline (Non-Wired)

Product Code: BLL

Helicopter Short Lines

Product Code: BSLR

Heavy-Lift Helicopter Longline

Product Code: DLH

Helicopter Longline (Wired)

Product Code: DLL

Helicopter Longline (Non-Wired)

Product Code: BLL

Helicopter Short Lines

Product Code: BSLR

Barry D.E.W. Line® Dielectric Helicopter Longlines

Barry D.E.W. Line® Dielectric Helicopter Longline

Product Code: BLLNDR

Barry D.E.W. Line® Dielectric HEC Longline

Product Code: BLLNDR-H

Barry D.E.W. Line® Dielectric Helicopter Longline

Product Code: BLLNDR

Barry D.E.W. Line® Dielectric HEC Longline

Product Code: BLLNDR-H

Barry Specialty Longlines

Human External Cargo HEC

Product Code: P-HEC

Barry Drone/UAV Systems

Product Code: BARRY-DRONE-UAV-SYSTEMS

Specialized Rope Systems for Airborne Geophysical Surveying

Product Code: HELICOPTER-TOW-LINES

Helicopter Lifting Sling Assembly

Product Code: BLSH4

Our line of helicopter longline systems represents a transformative evolution in aviation, enabling versatile external load operations that are essential for utility tasks, firefighting, human external load missions, and cutting-edge UAV applications.

With a history of pioneering innovations and milestones, including increased payload capacity, lightweight materials, advanced load monitoring, and compatibility with tandem rotor and heavy lift helicopters, our products stand out. Barry has been at the forefront, offering in-depth user manuals, airworthiness engineering analysis, and longline inspection training.

From powering utility industry needs to aiding in firefighting, disaster relief and humanitarian missions, human external load operations, and adapting products for geophysical and UAV/drone applications, our longline systems continue to shape the aviation industry's capabilities, ensuring precision and efficiency across diverse sectors.

Barry helicopter longlines are supported by Airworthiness Analysis to FAA CFRs, CARs and EASA requirements, and are used in over 75 countries worldwide. These products carry a 10-year service and shelf life, and many will include EC/CE Compliant Markings for Europe.

Barry is pleased to offer product inspection training for all levels, and AOG product support.

We also recommend:

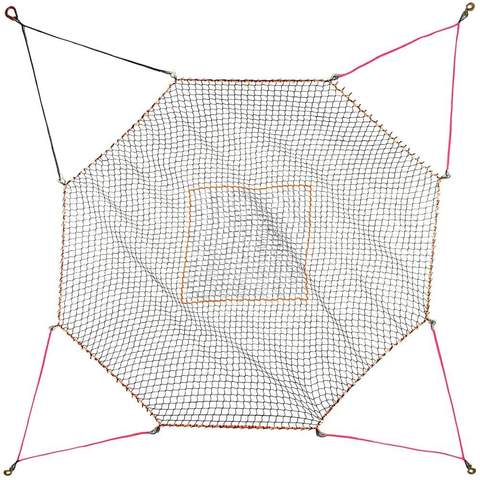

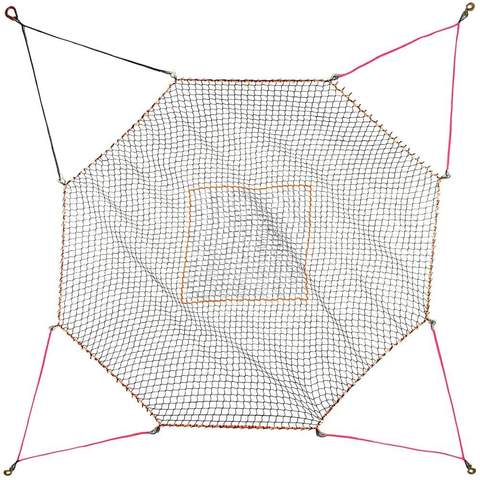

Helicopter Cargo Net - 6 600 lb WLL - Octagonal - Model C1

Product Code: HCN-C1

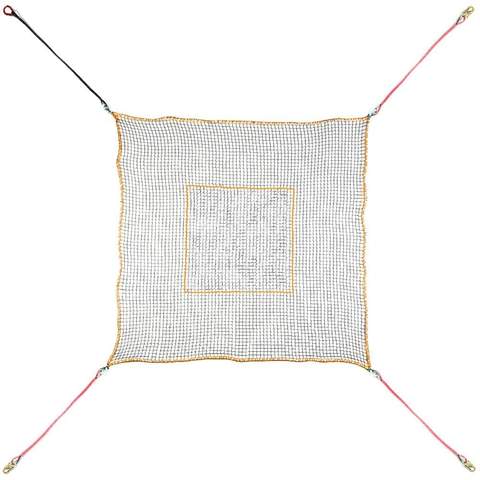

Helicopter Cargo Net - 3 000 lb WLL - Square - Model B1

Product Code: HCN-B1

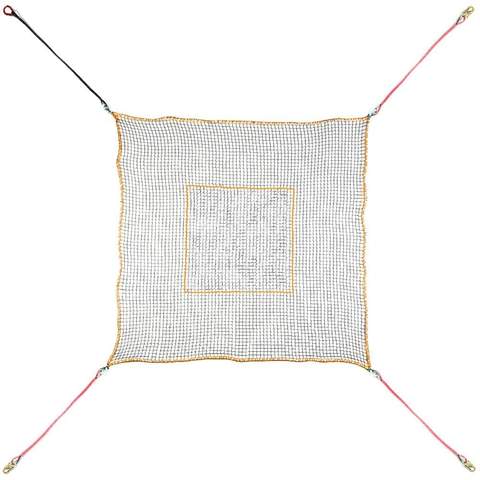

Helicopter Cargo Net - 1 500 lb WLL - Square - Model A1

Product Code: HCN-A1

Longline Jacket with Double Zipper

Product Code: LLJZZ

Longline Ballast (Weighted End Cover)

Product Code: LLEC-W25NC-L8

Human External Cargo HEC

Product Code: P-HEC

Barry Drone/UAV Systems

Product Code: BARRY-DRONE-UAV-SYSTEMS

Specialized Rope Systems for Airborne Geophysical Surveying

Product Code: HELICOPTER-TOW-LINES

Helicopter Lifting Sling Assembly

Product Code: BLSH4

Our line of helicopter longline systems represents a transformative evolution in aviation, enabling versatile external load operations that are essential for utility tasks, firefighting, human external load missions, and cutting-edge UAV applications.

With a history of pioneering innovations and milestones, including increased payload capacity, lightweight materials, advanced load monitoring, and compatibility with tandem rotor and heavy lift helicopters, our products stand out. Barry has been at the forefront, offering in-depth user manuals, airworthiness engineering analysis, and longline inspection training.

From powering utility industry needs to aiding in firefighting, disaster relief and humanitarian missions, human external load operations, and adapting products for geophysical and UAV/drone applications, our longline systems continue to shape the aviation industry's capabilities, ensuring precision and efficiency across diverse sectors.

Barry helicopter longlines are supported by Airworthiness Analysis to FAA CFRs, CARs and EASA requirements, and are used in over 75 countries worldwide. These products carry a 10-year service and shelf life, and many will include EC/CE Compliant Markings for Europe.

Barry is pleased to offer product inspection training for all levels, and AOG product support.

We also recommend:

Helicopter Cargo Net - 6 600 lb WLL - Octagonal - Model C1

Product Code: HCN-C1

Helicopter Cargo Net - 3 000 lb WLL - Square - Model B1

Product Code: HCN-B1

Helicopter Cargo Net - 1 500 lb WLL - Square - Model A1

Product Code: HCN-A1

Longline Jacket with Double Zipper

Product Code: LLJZZ

Longline Ballast (Weighted End Cover)

Product Code: LLEC-W25NC-L8

Barry's publications on Helicopter Longlines & Cargo Nets

Instructions Manuals

Product Training:

Barry Helicopter Longline Inspection & Maintenance

Trademark

Dyneema® is a trademark of DSM. Use of this trademark is prohibited unless strictly authorized.

Technora® is a registered trademark of Teijin Ltd.

Barry D.E.W. Line® and all Barry D.E.W Line® products are trademarks of Barry Cordage Ltd. Use of these trademarks is strictly prohibited unless authorized by Barry.